Product Description

Handheld Fiber Laser Welding Machine

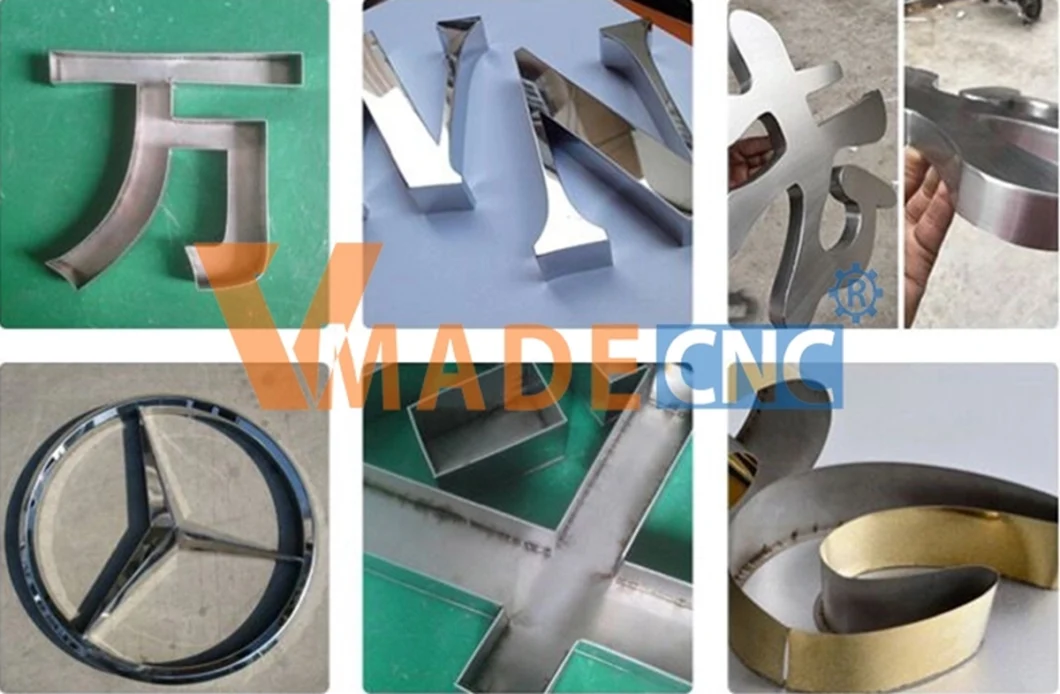

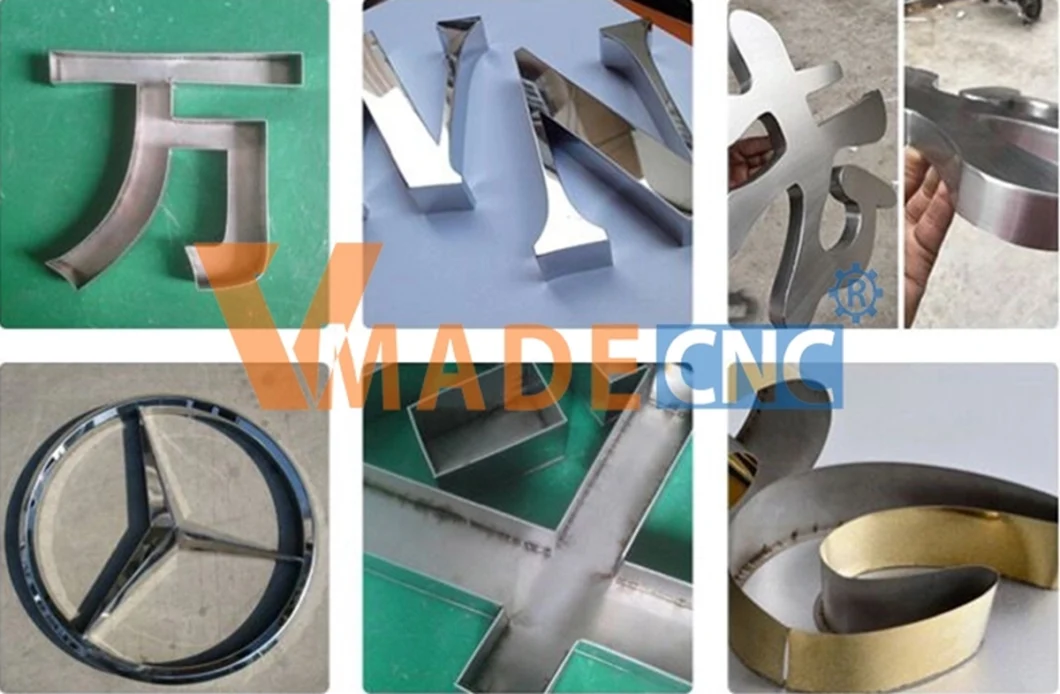

VMADE Handheld Fiber Laser Welding Machine is a new type high-power, high-end continuous welding tool which adopts a high-quality fiber laser source to produce a fiber optic beam. After transmission processing, the light is focused on the workpiece to achieve continuous welding. It avoids the two thresholds of thermal strain and post-treatment, and is environmentally friendly and pollution-free, greatly improving the joint strength and quality of welding. Replacing the previously fixed light path with a hand-held type not only facilitates the welding of molds, advertising characters, kitchen utensils, doors and windows, etc., but also makes laser welding possible in outdoor operations, which indicates that the traditional welding of electric welding, argon arc welding, etc. will be replaced by laser welding.

Features

1. Small, beautiful and smooth weld seam, no pores, high weld depth ratio and high welding quality, the toughness after welding is comparable to that of the parent material.

2. Simple operation, large laser power, high efficiency, no consumables, long-term processing is possible;

3. Spot welding, butt welding and precision welding can be realized for thin-walled materials and precision parts;

4. Obvious advantages in special-shaped welding, splicing welding and spot welding, large laser power is sufficient to weld metals that is not easily to be melted such as gold, silver and copper. It can weld small and delicate geometric areas.

Detailed Images

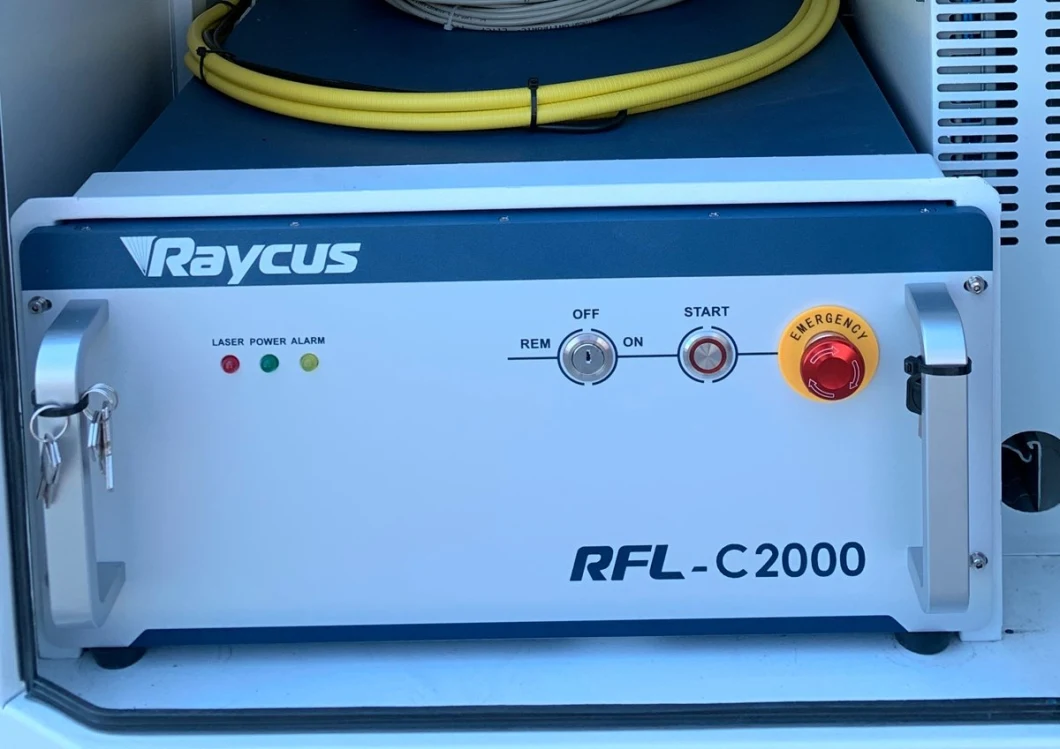

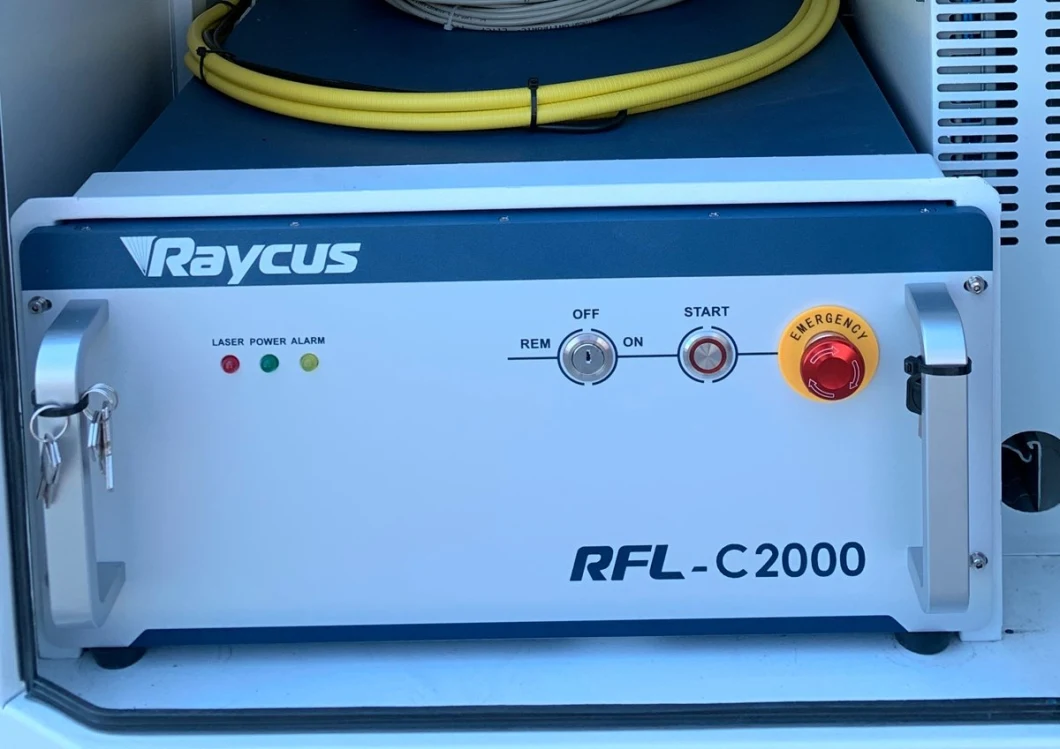

Raycus Fiber Laser Source

• 100,000 hours of lifetime, free maintenance;

• High electro-optical conversion efficiency (up to 25-30%), excellent beam quality, high energy density, and reliability, a wide modulation frequency;

• Low energy consumption, only 20%-30% of the traditional CO2 machine

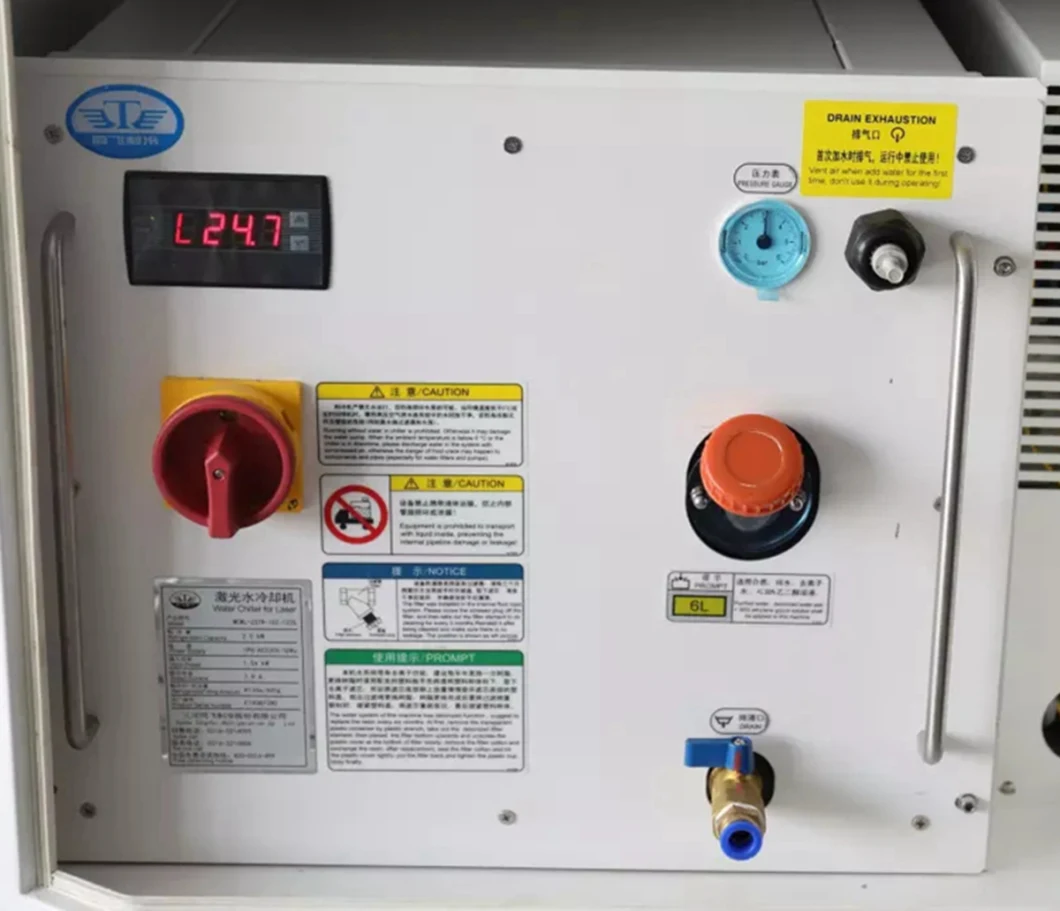

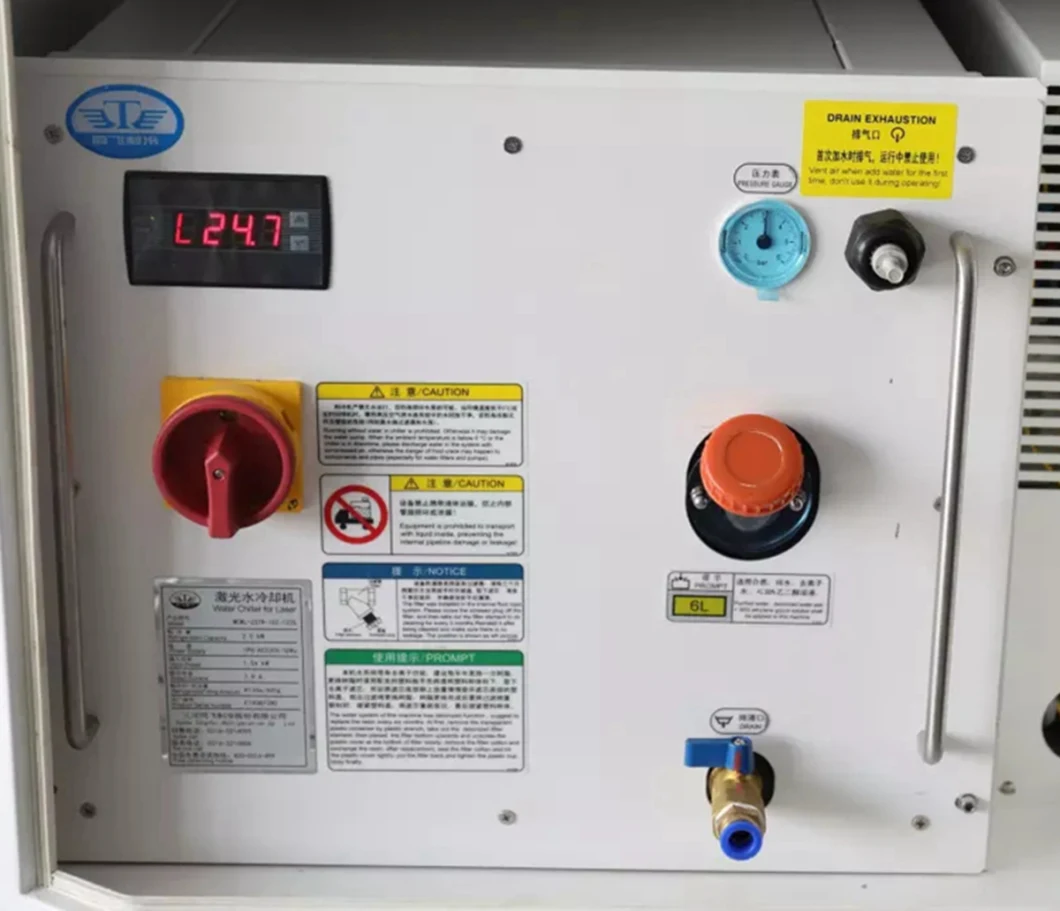

Tongfei Industrial Water Chiller

• Automatically adjust the temperature according to different working environment, no need to change settings parameters;

• Intelligent dual temperature dual control mode to satisfy different needs of a fiber laser device and the optics;

• Multiple alarm protection;

• CE certification; RoHS certification; REACH certification.

WSX ND18 Hand-held Wobble Laser Welding Head+System Solution

1.This welding head could be widely used in complex and irregular welding process such as cabinets, kitchen, staircase, shelf, gridiron, stainless steel door and window guardrail, distribution box, stainless steel furniture and other industries. It is a perfect replacement of traditional argon arc welding, in welding thin stainless steel plate, iron plate, aluminum plate and other metal materials.

2.Smart internal design and interactive control system expand the tolerance range and welding width of the processing parts, and solve the disadvantage of minor laser welding spot, and provide better welding forming.

3.Light shape, Ergonomic design, advanced structure, and reliable performance ensure comfort grip and simple operation.

4.Nice welding seam, fast welding speed, no consumables, no welding marks, no discoloration, no later polish.

5.This head could be equipped with a variety of angular nozzles to meet the welding needs of different products.

Parameters

Sample Picture

FAQ

1. This laser weld machine also need others?

It only need nitrogen gas as protective gas.and also can use argon.but nitrogen is more cheaper than argon.

2.Does need professional technical to operate this machine?

No. this machine operate is very easy. everyone can operate it . it only need about 10mins can learn it.

3.What is consumables life?

For nozzles and protective lens, both can use about 30 days.

4.It need wire or not ?

We have both model.one is without wire feeder , it use for material section is vertical.such as fiber laser cutting workpiece. The other is with wire feeder.It use for material have a little gap.and it can increase welding strength and penetration.

5.What type of welding wire is needed ?

Using gas shielded welding wire, diameter:0.8mm,1.0mm and 1.2mm.

6.If i buy machine without wire feeder, can add wire feeder later?

No. because the laser head and controller are all different.

If you have any questions, Please contact us

Handheld Fiber Laser Welding Machine

VMADE Handheld Fiber Laser Welding Machine is a new type high-power, high-end continuous welding tool which adopts a high-quality fiber laser source to produce a fiber optic beam. After transmission processing, the light is focused on the workpiece to achieve continuous welding. It avoids the two thresholds of thermal strain and post-treatment, and is environmentally friendly and pollution-free, greatly improving the joint strength and quality of welding. Replacing the previously fixed light path with a hand-held type not only facilitates the welding of molds, advertising characters, kitchen utensils, doors and windows, etc., but also makes laser welding possible in outdoor operations, which indicates that the traditional welding of electric welding, argon arc welding, etc. will be replaced by laser welding.

Features

1. Small, beautiful and smooth weld seam, no pores, high weld depth ratio and high welding quality, the toughness after welding is comparable to that of the parent material.

2. Simple operation, large laser power, high efficiency, no consumables, long-term processing is possible;

3. Spot welding, butt welding and precision welding can be realized for thin-walled materials and precision parts;

4. Obvious advantages in special-shaped welding, splicing welding and spot welding, large laser power is sufficient to weld metals that is not easily to be melted such as gold, silver and copper. It can weld small and delicate geometric areas.

Detailed Images

Raycus Fiber Laser Source

• 100,000 hours of lifetime, free maintenance;

• High electro-optical conversion efficiency (up to 25-30%), excellent beam quality, high energy density, and reliability, a wide modulation frequency;

• Low energy consumption, only 20%-30% of the traditional CO2 machine

Tongfei Industrial Water Chiller

• Automatically adjust the temperature according to different working environment, no need to change settings parameters;

• Intelligent dual temperature dual control mode to satisfy different needs of a fiber laser device and the optics;

• Multiple alarm protection;

• CE certification; RoHS certification; REACH certification.

WSX ND18 Hand-held Wobble Laser Welding Head+System Solution

1.This welding head could be widely used in complex and irregular welding process such as cabinets, kitchen, staircase, shelf, gridiron, stainless steel door and window guardrail, distribution box, stainless steel furniture and other industries. It is a perfect replacement of traditional argon arc welding, in welding thin stainless steel plate, iron plate, aluminum plate and other metal materials.

2.Smart internal design and interactive control system expand the tolerance range and welding width of the processing parts, and solve the disadvantage of minor laser welding spot, and provide better welding forming.

3.Light shape, Ergonomic design, advanced structure, and reliable performance ensure comfort grip and simple operation.

4.Nice welding seam, fast welding speed, no consumables, no welding marks, no discoloration, no later polish.

5.This head could be equipped with a variety of angular nozzles to meet the welding needs of different products.

Parameters

Model No. | VLW1000W/1500W/2000W |

Laser Type | Continuous Fiber Laser |

Laser Power | Raycus 1000W/1500W/2000W(Option: JPT/IPG) |

Laser Wavelength | 1070nm+/-5nm |

Welding Speed | 0~120mm/s |

Optical Fiber Laser Length | Standard 5m(Option: 10m/15m) |

Cooling Method | Industrial Water Cooling |

Welding Thickness | 0~10mm |

Optimal operating environment | Temperature: 15~35ºC Humidity: 20% -80% |

Operating Voltage | AC220V/50Hz |

Average Consumed Power | 2000~4000W |

Pulse Width | 0.1-50MS |

Focal Spot Diameter | 0.2-3.0mm |

Dimensions | 93*60*88cm |

Weight | 200kg |

Sample Picture

FAQ

1. This laser weld machine also need others?

It only need nitrogen gas as protective gas.and also can use argon.but nitrogen is more cheaper than argon.

2.Does need professional technical to operate this machine?

No. this machine operate is very easy. everyone can operate it . it only need about 10mins can learn it.

3.What is consumables life?

For nozzles and protective lens, both can use about 30 days.

4.It need wire or not ?

We have both model.one is without wire feeder , it use for material section is vertical.such as fiber laser cutting workpiece. The other is with wire feeder.It use for material have a little gap.and it can increase welding strength and penetration.

5.What type of welding wire is needed ?

Using gas shielded welding wire, diameter:0.8mm,1.0mm and 1.2mm.

6.If i buy machine without wire feeder, can add wire feeder later?

No. because the laser head and controller are all different.

If you have any questions, Please contact us